أرسل لنا رسالة

Matte iron grinding machinery process

PGM converter matte mineral characteristics and effects

2017910 Typical matte composition is 38% Fe, 16% Ni, 10% Cu and 30% S ( Nolet, 2014 ). The process route for the production of base and platinum-group metals from natural sulfide concentrates commonly requires the conversion of high‑iron furnace matte into an

get price

PGM converter matte mineral characteristics and effects

2017910 Typical matte composition is 38% Fe, 16% Ni, 10% Cu and 30% S (Nolet, 2014). The process route for the production of base and platinum-group metals from

get price

Grinding Processes SpringerLink

Grinding is an essential process in the manufacture of virtually all types of mechanical equipment and cutting tools. For example, the production of rolling element bearings,

get price

Iron Processing Equipment, Process Flow, Cases

2019823 3 Fine screening and grinding process. Features The fine sieving and re-grinding process is an effective method to improve the grade of iron concentrate. The fine mesh screen and return the coarse-grained

get price

Development of a Novel Grinding Process to Iron Ore

2020328 The present study considers a novel milling process applying only HPGR as a re-regrind stage after concentration. The amount of successive ground product

get price

Extraction of Iron, Iron Mining, Iron Ore Processing Xinhai

According to the specific magnetization coefficient, the iron ores can be divided into strong magnetic minerals and weak magnetic minerals, which provides a basis for the extraction

get price

PAPER OPEN ACCESS

this process nickel is deposited from purified nickel chloride solutions at the surface of cathode by using direct current. 4. Grinding process Nickel matte particle size plays an

get price

Principles of Modern Grinding Technology ScienceDirect

1 Introduction. In the second half of the twentieth century, it was recognized that grinding is a strategic process for high-technology applications. It was realized, for example, by

get price

Mechanism of magnetite iron ore concentrate morphology

2022121 Toward the influence of iron oxide morphology on the grinding and filtration processes and on the cold crushing strength (CCS) of heat-treated iron ore pellets Miner.

get price

Wan, Xingbang; Shen, Leiting; Jokilaakso, Ari; Eriç,

2003; White et al. 2015 and Jun et al. 2018) and assisting process control as well as equipment design.The modelling efforts of copper FS has been reviewed by Taskinen et

get price

PGM converter matte mineral characteristics and effects

2017910 There is little in-depth study on the downstream processing characteristics of granulated PGM-containing converter matte, particularly related to grinding and liberation behavior closely associated with leaching, and also as a function of iron endpoint specific mineralogy.Moreover, there is limited physical property data available, such as hardness

get price

Principles of Modern Grinding Technology ScienceDirect

Every aspect of the grinding process--techniques, machines and machine design, process control, and productivity optimization aspects--come under the searchlight. The new edition is an extensive revision and expansion of the first edition covering all the latest developments, including center-less grinding and ultra-precision grinding.

get price

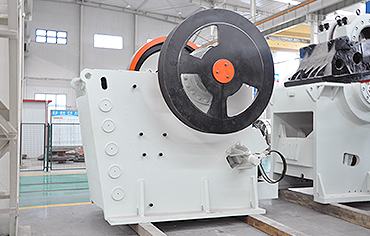

Grinding Machine: Parts, Working, Operations,

202339 A grinder is commonly used to precisely shape and finish the given materials with low surface roughness and high surface quality. A grinding machine is a type of machine used to grind workpieces. It

get price

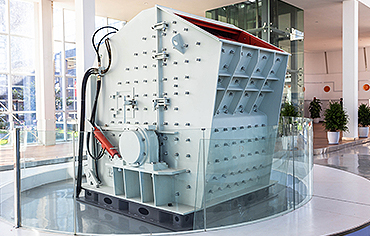

Matte iron grinding machinery process

Tool Post Grinding Machine The tool post grinding machine, see Figure 5 Iron Ore Processing,Crushing,Grinding Plant The beneficiation process should be as efficient and simple as possible, such as the development of energy-saving equipment, and the best possible results with the most suitable process.

get price

PGM converter matte mineral characteristics and effects

2017910 Abstract. There is little in-depth study on the downstream processing characteristics of granulated PGM-containing converter matte, particularly related to grinding and liberation behavior closely associated with,and also as a function of iron endpoint specific mineralogy. A Nano-indentation tester was used to measure the indentation

get price

Iron Ore Processing, General SpringerLink

20221020 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

get price

A new technological approach to the granulation of slag

2021113 The technological factors required to improve the operational properties of granulated metallurgical slags demanded in the building industry have been analyzed. In order to satisfy these factors, a new technology for hydro-vacuum granulation of slag melts (HVG) has been developed. It is shown that the main advantage of the proposed HVG

get price

The pros and cons of reductive matte smelting for PGMs

201151 The emission of SO 2 (sulphur dioxide) from furnaces and converters is hard to avoid when using a sulphur-based matte-smelting process. However, the ConRoast process does not rely on the presence of sulphur, as it smelts essentially sulphur-free (or low-sulphur) material in a DC arc furnace and collects the valuable metals in an iron alloy.

get price

GitHub

sbm electrochemical grinding process for ironElectrochemical Grinding Technology Group belgian press electrochemical grinding process for iron jakestales.Electrochemical Grindi

get price

Element Distribution and Migration Behavior in the Copper

Copper slag is a solid pollutant with high recyclability. Reduction and separation are regarded as effective disposal methods. However, during the melting process, the separation and migration behavior of elements in the copper slag is complicated. Thus, the formation of pollutants cannot be controlled merely by optimizing the operation

get price

Grinding Mills — Types, Working Principle

2018817 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up to approximately 50 mm. (2 in.) and

get price

(PDF) COPPER MATTE GRANULATION AT THE

200611 Abstract and Figures. Kennecott Utah Copper adopted Outokumpu Flash Smelting and Kennecott-Outokumpu Flash Converting in 1995, a process based on granulating high grade copper matte. While

get price

Wan, Xingbang; Shen, Leiting; Jokilaakso, Ari; Eriç,

2003; White et al. 2015 and Jun et al. 2018) and assisting process control as well as equipment design.The modelling efforts of copper FS has been reviewed by Taskinen et al. (2019). The reactions for generating and separation of the sulphide matte and iron silicate slag occur mostly below the reaction shaft, on the settler surface.

get price

Different Types of Metal Finishes Thomasnet

202358 Sherardizing is a process used to coat small steel parts such as bolts and washers with a corrosion-resistant zinc-iron alloy. Parts are tumbled in a heated drum containing zinc dust, producing a highly corrosion-resistant finish. In high-volume production runs, a barrel-finishing machine is a fast and efficient coating solution.

get price

Grinding Processes SpringerLink

Grinding is an essential process in the manufacture of virtually all types of mechanical equipment and cutting tools. For example, the production of rolling element bearings, automotive components, power generation equipment, and computer and electronic components is critically dependent on grinding processes.

get price

Exceptional Barite Processing Methods and Machines Fote Machinery

2023320 To fully dissociate useful barite minerals, ball mills are commonly used to grind barite rocks. Generally, the grinding fineness of barite-200 is 85~90%, and a two-stage grinding process is often used. In view of the differences in the properties of barite ores, the optimum grinding fineness needs to be determined experimentally.

get price

Beneficiation of Magnetically Separated Iron-Containing

20221027 size with 52 percent average iron grade was crushed and ground to ( 0.1) mm size. The required quantity of 60 percent iron concentrate was produced by a multi-stage cleaner separation using the laboratory magnetic separator being studied. We note that this ore is difficult to process, and a finer grinding is required to increase Fe grade.

get price

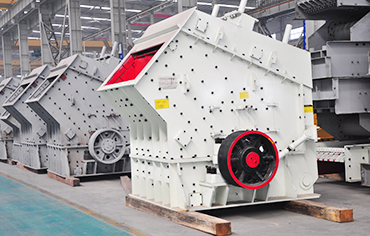

Industrial Grinding Machines: How it Works General Kinematics

201889 by General Kinematics, August 9, 2018. Material grinding (also called attrition milling) is the process by which materials are mechanically broken into fine granules and is an essential step in many industrial processes. Considered a subset of cutting, grinding is used in the metal-cutting process. Grinding machinery can be used to reduce

get price- مطحنة توربو المنتج

- الشركات السويدية لصناعة المعدات الثقيلة

- الصين GF الثقيلة كسارة

- مطلوب كسارة في سلطنة عمان

- شركة هلتيير لصناعة المعدات الثقيلة

- اسعار بلاطات الكسارة

- آلات التصوير المتطورة

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- الهيكل الاداري محجر فوسفات

- وكيل ماكنات تطريز كوريه بالجزائر

- أفران صناعة المعادن

- السواقى والبريمات فى المطاحن