أرسل لنا رسالة

Ore crushing feeding motor speed

Crushing characteristics and performance evaluation of iron

The influence of the eccentric speed on the crushing rate is weak, but the crushing rate decreases with the increase of the closed side setting and eccentric angle. The variation trend of the product size is consistent with that of the crushing rate.

get price

Mineral Processing Crushing System Based on Fuzzy

2022522 Crushing is a key link in the process of mineral processing industry. There are many factors affecting crushing efficiency, among which feeding control is the most

get price

Ore Crushing SpringerLink

2023722 Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm. The maximum crushing ratio of coarse

get price

Minerals Free Full-Text Feeding Material

2022319 The good classification performance for coal, iron and can satisfy the practical demands to remove the harmful feeding materials, which provides the core technical support for the

get price

Gyratory and Cone Crusher ScienceDirect

201611 One of the important factors in the operation of a gyratory crusher is to determine the speed of gyration to attain a specific product size at a specific rate. In

get price

Optimal-Setting for Ore and Water Feeding in

2021623 The data include the crushing ore size, ore grade, magnetic tube m F e, magnetic tube recovery rate, raw ore F e O content, raw ore m F e content, the water feed rate, and the fresh ore feed rate.

get price

Modeling and Improving the Efficiency of Crushing Equipment

2023516 The proposed system uses an ultrasonic sensor with variable motor speed to control the vibration speed of the screen preceding the crusher to obtain feed rate

get price

(PDF) Ore crushing in the high-pressure roller-press as a

2021219 Ore crushing in the high-pressure roller-press as a modelling object under stochastic properties of feed materials February 2021 Eastern-European Journal of

get price

Fractal dimension of crushing products: effects of feed size

20201221 Read this article. In mineral crushing operations, the feed rate and feed size distribution affect the crushing rate and particle size distribution of the crushed

get price

Developments in iron ore comminution and classification

201511 Feeder speed: feeder speed helps adjust the height of ore within the crusher bowl. Crusher amps: crusher current (amps) is an indication of how hard the crusher is

get price

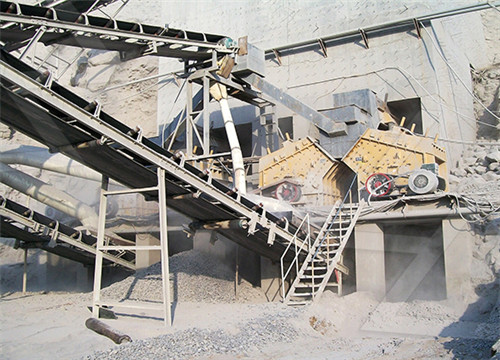

AMIT 135: Lesson 5 Crushing Mining Mill

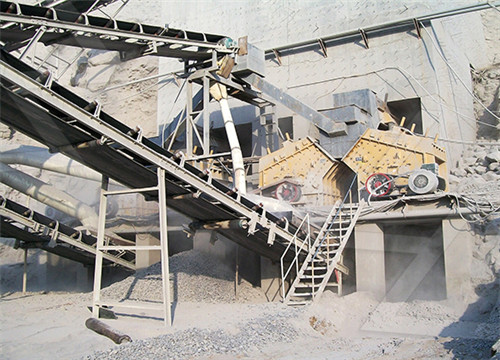

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

get price

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020414 Maximum crushing efficiency, when using Bi-Flow® in a given crusher range, can be realized when the following parameters have been selected: • Maximum motor size for the relevant crusher size. • Tip speed selected at 0.9-1Kw / Tonne rotor throughput. • Crusher operated at maximum motor amps. with rotor only feed.

get price

Developments in iron ore comminution and classification

201511 The Arrium Whyalla magnetite grinding circuit is fed with < 32 mm feed from a three-stage crushing plant and consists of two HPGR lines (1.4 m diameter × 1.4 m long, with two 900 kW motors) in closed circuit with a screen of 3 mm and, after the first magnetic separation stage, with another screen of 0.7 mm.

get price

Optimal-Setting for Ore and Water Feeding in Grinding

2021623 The characteristics contain the crushing ore size f 1, ore grade f 2, magnetic tube m F e f 3, magnetic tube recovery rate f 4, raw ore F e O content f 5, raw ore m F e content f 6 and overflow particle size target value f 7. The characteristic solutions are the ball mill ore feed j 1 and water feed j 2. The case weight is defined as β.

get price

Reduction of Fragment Size from Mining to Mineral

2022104 2.1 Energy. Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines. As mentioned in Sect. 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from

get price

Gyratory and Cone Crusher ScienceDirect

201611 inherent and total moisture content in the ore/rock, 3. feed distribution in the crushing area and the bulk density of the feed, 4. hardness of ore (work index), 5. recirculating load in the case of closed circuit crushing. The operation of crushers depends on the gyrating speed and the open and closed set positions.

get price

DISCUSSION. THE EVOLUTION OF VARIOUS TYPES OF

2020122 260 tons and was driven by a motor of 350 HP. He ought perhaps to explain that, owing to their slower speed, those giants did not give the greatest outputs. A machine with a feed-opening 72 inches by 48 inches might be run considerably faster than one with an opening 84 inches by 66 inches, and its tonnage output would

get price

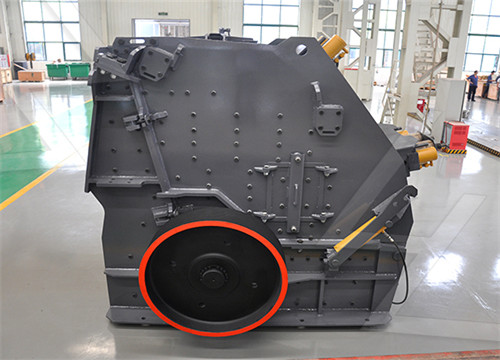

Crusher Motor Powered By UMPS Drive Electrical India

201825 This saves ore materials from wastage and enhances productivity, energy saving and revenue of the mining operation. Gyratory crusher is the principal equipment in the iron ore processing plant with multistage crushing. The design of the crusher drive including motor and power system has to be robust and of high reliability.

get price

Optimal-Setting for Ore and Water Feeding in Grinding

2021623 The characteristics contain the crushing ore size f 1, ore grade f 2, magnetic tube m F e f 3, magnetic tube recovery rate f 4, raw ore F e O content f 5, raw ore m F e content f 6 and overflow particle size target value f 7. The characteristic solutions are the ball mill ore feed j 1 and water feed j 2. The case weight is defined as β.

get price

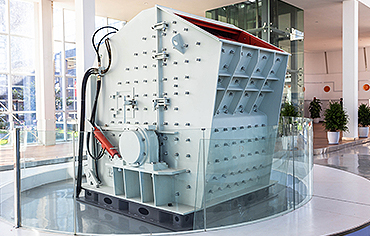

Ore Crusher PE Series Jaw Type Ore Crusher AIMIX

Diemeter of large end of crushing cone(mm): 1295 Adjusting range of discharging opening(mm): 13-31 Feed opening size of the open edges when recommending the min discharge opening (mm): 137 Max feed size(mm): 115 Processing capacity(t/h): 108-181 Main motor power(kw): 160 Weight(kg): 22460

get price

Comminution and classification technologies of iron ore

202211 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

get price

CNA But multistage ore crushing device of automatic feed

The invention discloses an automatic feeding type multistage ore crushing device, which comprises: a base; the crushing device comprises a crushing shell, wherein four corners of the bottom end of the crushing shell are fixedly provided with first supporting legs, and the first supporting legs are fixedly arranged at the top end of a base; the crushing shell is

get price

Ore crushing device is used in mine Google Patents

The invention discloses an ore crushing device for mines, which comprises a box body, wherein a plurality of feeding cylinders are arranged at the upper end of the box body, ores enter the box body through the feeding cylinders, a discharge hole is formed in the lower end of the box body, a crushing device is arranged in the box body, a first telescopic rod is

get price

A review of modeling and control strategies for cone crushers

2021815 When the eccentric speed is increased, the processed rocks are subject to more crushing events, and thus, a smaller product particle size distribution is observed. Slower eccentric speed values, however, lead to a product with a better shape and higher crushing capacity (Quist, 2012). 2.6.6. Feed conditions

get price

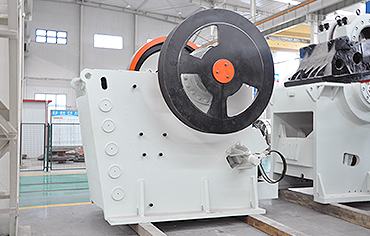

Five Types of Crusher in the Mineral Processing LinkedIn

2020916 The crushing cavity of jaw crushers is deep without dead zone, so the feeding capacity and production of this type of crusher have been greatly increased, featured by large reduction ratio and

get price

China Ore Feeding, Ore Feeding Manufacturers, Suppliers,

China Ore Feeding manufacturers Select 2023 high quality Ore Feeding products in best price from certified Chinese Ore, Ore Equipment suppliers, wholesalers and factory on Made-in-China

get price

Special Issue "Grinding Modeling and Energy Efficiency in Ore

2022831 The grinding speed of ore and its component minerals decreased exponentially with the grinding time, and the instantaneous grinding speed of 0 min was negatively correlated with the feed sizes. Simulations indicated that a capacity increase of 12% would be achieved in the existing grinding circuit by further crushing 35% of SAG

get price

Feeding device of electromagnetic ore crusher Google

feeding device ore crusher supporting plate support Prior art date 2020-04-15 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Granted Application number CN.8A Other languages Chinese (zh

get price

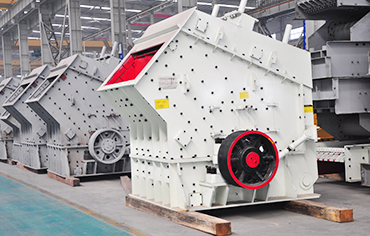

(PDF) SIZE REDUCTION BY CRUSHING METHODS

201734 Crushing of ore and minerals. crushers have a large feed opening and a groov ed mantle, process .And during the operation ,driv en by the motor ,the rotor will proceed a high speed and the .

get price

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft,mantle,concaves,cone,eccentric bushing,drive,crown gear,frame, and tramp release mechanism (mechanically or hydraulically actuated). Cone Crusher Components. Top ShellSpider Cap Assembly. The feed is fed by conveyors to a feed

get price- مطحنة توربو المنتج

- الشركات السويدية لصناعة المعدات الثقيلة

- الصين GF الثقيلة كسارة

- مطلوب كسارة في سلطنة عمان

- شركة هلتيير لصناعة المعدات الثقيلة

- اسعار بلاطات الكسارة

- آلات التصوير المتطورة

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- الهيكل الاداري محجر فوسفات

- وكيل ماكنات تطريز كوريه بالجزائر

- أفران صناعة المعادن

- السواقى والبريمات فى المطاحن