أرسل لنا رسالة

iron ore secondary crushing

Comminution and classification technologies of iron ore

202211 Iron ore crushing and screening. Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route or through the electrical arc furnace

get price

Crushing characteristics and performance evaluation of iron ore

Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the

get price

Developments in iron ore comminution and classification

201511 As shown in Figure 8.7, the proposed processing plant will include the following components: three remote primary/secondary crushing stations, overland

get price

Ore Beneficiation an overview ScienceDirect Topics

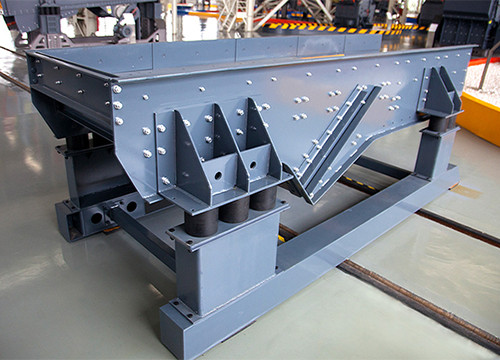

Secondary crushing and screening can result in further classification and grading of iron ore. The fines fraction is usually of lower grade compared with lump ore. View chapter

get price

Iron ore beneficiation: an overview ScienceDirect

202311 In this iron ore deposits (mentioned above), the iron ore was crushed using three stages of crushing to a size below 32 mm and then was subjected to beneficiation.

get price

(PDF) Processing of Magnetite Iron

200911 The iron ore beneficiation plants normally include a series stages of size reduction (in order to achieve the desired liberation degree), increasing iron ore grade (magnetic separation), and

get price

(PDF) SIZE REDUCTION BY CRUSHING METHODS

201734 Crushing of ore and minerals. ,it can be used as secondary mid crushing work .We can change the gap between t 9.00% of Iron (II) oxide (Fe2O3) while samples from Pit 5 to Pit 10 in the

get price

How iron ore is crushed? LinkedIn

Published Mar 13, 2023 + Follow Iron ore is a mineral that is found in rocks and minerals from which metallic iron can be extracted. The crushing process is an essential step in the...

get price

Simheuristic-based decision support system for

202091 There are 3 sequential crushing stages to gradually reduce the particle size of the iron ore: secondary, tertiary and quaternary; 3. The secondary crushing aims to

get price

Iron ore extraction techniques ScienceDirect

202211 Iron ore reserves are normally found within a few meters from the ground surface, and most of the major mines of the world are operating an opencut system,

get price

Crushing characteristics and performance evaluation of iron ore

1. Introduction. Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the

get price

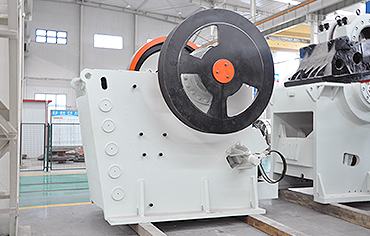

Primary vs. Secondary Crushers: Understanding

2023228 They are ideal for crushing hard and abrasive materials such as granite, basalt, and iron ore. Roll crushers: These crushers use compression force to crush the material. They are designed to handle

get price

Challenges and opportunities in the iron ore

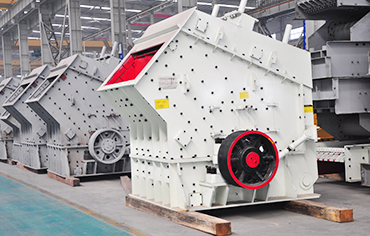

201988 For high-hardness iron ore, a cone crusher can be used for the secondary crushing equipment. The mpl short-headed cone crusher can achieve a fine crushing effect of 3 to 13mm, which can fully meet the

get price

SNIM Open Pit Iron Ore Mining Mauritania Mining

2021513 SNIM Open Pit Iron Ore Mining Mauritania. Miferma (Mines de Fer de Mauritanie) was created in 1952 to exploit iron ore deposits in the Kedia d'Idjil area of north. Producer of. Primary and secondary crushing is done at Tazadit and the ore is railed to Nouadhibou in trains of up to 220 cars, each carrying 84t. The ore is stockpiled then

get price

Minerals Free Full-Text Pre-Processing to Increase the

202266 Due to the existing iron ore production and logistic system in the region (Carajás and S11D), Vale decided to install a 6 Mtpa dry plant to process such an iron ore deposit. It comprises of a three-stage crushing and screening, whose product is predicted to be 90% passing size (P 90 ) of 19 mm.

get price

Ore Beneficiation an overview ScienceDirect Topics

In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated. This screening is an essential step prior to their separation into ore product and waste rock. Secondary crushing and screening can result in further classification and grading of iron ore.

get price

Gyratory and Cone Crusher ScienceDirect

201611 5.1. A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°.

get price

(PDF) SIZE REDUCTION BY GRINDING METHODS

201734 Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, crushing or 40 to 55mm for secondary. By adopting secondary crushing that will reduce the size .

get price

Beneficiation of Iron Ores IspatGuru

201443 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial

get price

PROJECT DESCRIPTION Winning Consortium Simandou

2023111 Winning Consortium Simandou (“WCS”) plans on commencing an iron ore mine in the Kankan Region, Kérouané Prefecture of Guinea, Africa. The Simandou area (Figure 1) is split into four mineable blocks, Block #1, #2, #3 and #4, of which Block #1 and Block#2 (Figure 2) are owned by WCS and is where the Simandou Project is located.

get price

Iron Ore Processing, General SpringerLink

20221020 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

get price

Life cycle assessment of iron ore mining and processing

201511 Mining of iron ore is a highly capital- and energy-intensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts considered in the study were embodied energy and greenhouse gas (GHG)

get price

(PDF) SIZE REDUCTION BY CRUSHING METHODS

201734 Crushing of ore and minerals. ,it can be used as secondary mid crushing work .We can change the gap between t 9.00% of Iron (II) oxide (Fe2O3) while samples from Pit 5 to Pit 10 in the

get price

Crushing 101 Different types of crushers for distinctive needs

20201217 Mechanized crushing has existed for 150 years. Despite the fine differences between the equipment, at the end, they all have the same objective: to reduce the size of rocks and, of course, to supply the market with products as varied as gravel for construction or iron ore for the steel sector.

get price

Global Iron Ore Crusher Market Overview 2023 by Top

202384 Global Iron Ore Crusher Market research offers a detailed and comprehensive analysis of the global market, with a particular focus on future projections. The report is structured into various

get price

Process simulations in mineralogy-based geometallurgy of iron

This study focussed on flowsheet simulation for mineralogical-based approach to geometallurgy of iron ores. Process unit models used were selected based on their applicability at particle level for iron ore beneficiation and flowsheet simulation. The feed streams for plant simulation were run-of-mine feed and forecast feed from ore textural

get price

How is iron ore crushed ready for processing? LinkedIn

20221223 First, the ore is subjected to a primary crushing process that reduces the size of the ore to a maximum size of about 6 inches. The crushed material is then transferred to a secondary crushing

get price

Iron ore extraction techniques ScienceDirect

201511 Iron ore was won by drilling and blasting (Figure 7.1).As mining technology generally developed, so did drilling techniques and the explosives used. Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as “dogger”) allowing mine drivages to be self-supporting. However, he states

get price

Life cycle assessment of iron ore mining and processing

202211 In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated. This screening is an essential step prior to their separation into ore product and waste rock. Secondary crushing and screening can result in further classification and grading of iron

get price

What Type of Crusher Is Best for Primary Crushing?

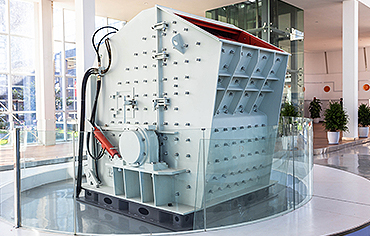

2021325 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more. Using a combination of impact, shear and attrition reduction methods,

get price- مطحنة توربو المنتج

- الشركات السويدية لصناعة المعدات الثقيلة

- الصين GF الثقيلة كسارة

- مطلوب كسارة في سلطنة عمان

- شركة هلتيير لصناعة المعدات الثقيلة

- اسعار بلاطات الكسارة

- آلات التصوير المتطورة

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- الهيكل الاداري محجر فوسفات

- وكيل ماكنات تطريز كوريه بالجزائر

- أفران صناعة المعادن

- السواقى والبريمات فى المطاحن