أرسل لنا رسالة

stone crushers for crush hardness rocks

7 Types of Stone Crusher and How to Choose the Best?

2021923 There are two crushing methods: "stone-on-rock" and "stone-on-iron". Application: "Stone-on-Stone" is suitable for abrasive materials with medium-hardness

:Mining EngineeringMining EquipmentBest Enhancement For StonecrusherHow to Choose The Right Crusher for Hard Rock? mpl Mill

Mark June 14, 2023 When we choose the right hard rock crusher, one of the important factors is the Mohs hardness of the rock. Different rocks have different Mohs hardness,

Types of Rock Crushers Quarry Crushing

1 Of course, there are also different styles of rock crushers. Compression-style jaw and cone crushers, for example, fit into the

: EzsolutionChoosing the right crusher for rock, stone, concrete and

Compression Crushers. Jaw and cone crushers use compression to squeeze rock between two surfaces until it shatters. These crushers generate an enormous amount of power

:Jaw CrushersRock CrushersRock Crusher MaterialStone CrusherEvaluation of size reduction process for rock aggregates in

202064 Cone crushers noted for their ability to crush hard, abrasive ores, and rocks are of prime importance in the secondary and tertiary stages of crushing operations. The

:Rock CrushersSecondary CrushingAuthor:Ekin KökenPublish Year:2020How to Crush Stone: A Simple Guide Machinery Partner

Some common rock examples are granite, caliche, and limestone. Small batches of soft rocks such as sandstone and caliche can be roughly broken up by a hydraulic breaker

(PDF) An experimental investigation on rock

2019418 PDF This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks.

:Jaw CrushersTypes Of Rock CrushersCrushing 101 Different types of crushers for

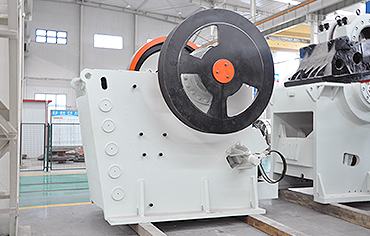

20201217 The very first crushers invented were jaw crushers, which are built to reduce the size of large materials and operate with high volume in primary crushing. Their main purpose is to reduce the material to a

Design, Fabrication and Testing of a Double Roll Crusher

2023923 hardness rocks provides impetus for industrial growth. Size reduction equipment are classified into crushers and grinders. Crushers are used for reducing large solid materials into feed sizes for grinding. The input and output particle sizes distinguish crushing from grinding rather than mechanism of size reduction [4].

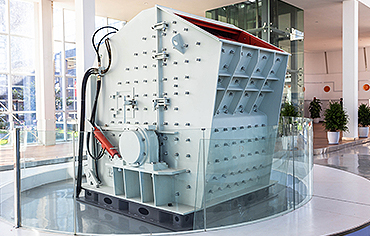

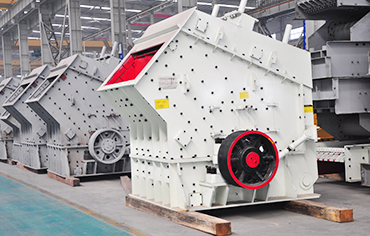

The 8 Differences between Impact Crusher and Cone Crusher

2020818 The hardness of materials crushed by impact crusher and cone crusher is different. Cone crusher is mainly used to crush some materials with higher hardness, such as granite, basalt, tuff, river pebble, etc. Impact crusher is often used to crush materials with small hardness and brittleness, such as limestone, limestone, etc. 4.

Comparing Different Types of Stone Crushers

The hardness, abrasiveness, size, and even moisture content of the material can determine which crusher is best suited. For instance, while jaw crushers are adept at handling hard rocks, impact crushers might be preferred for softer or more abrasive materials. Desired Output: The size and quality of the final product are crucial.

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022123 Compression crushers (Fig. 3.1a, b), which include primary gyratory, primary jaw, and secondary/tertiary cone crushers are normally not required to crush Gibbsitic and Boehmitic type bauxite. The compression-type machines are designed for the hardest, most competent, and abrasive feed materials that are typical in hard-rock mining

5 Granite Stone Crushers: Which is Best for Granite Crushing?

202314 Coarse crushing stage. 1) Jaw crusher. Jaw crusher is the most commonly used coarse crusher. It is not only used for hard rocks such as granite, but also basically used for coarse ore crushing, both soft and hard. The manufacturing process of jaw crusher is also relatively mature in China and abroad, so in the field of coarse crushing, jaw

Evaluation of size reduction process for rock aggregates in

202064 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several

7 Types of Stone Crusher and How to Choose the Best?

2021923 4. Sand Making Machine. The work of the impact sand making machine is continuous. It uses high-speed moving materials to strike iron, strike each other and friction between the materials to break. There are two crushing methods: "stone-on-rock" and "stone-on-iron".

en/cone crushers mohs hardness.md at main sbmboy/en

. Contribute to sbmboy/en development by creating an account on GitHub.

sbm/sbm marble crusher hardness.md at master sbm

sbm marble crusher hardnessmarble crusher mineral crushing process Marble Crushing Machine Price,Marble Crushing Machine.Cone Crusher for Rock,Marble Cone Crushers cone crusher is suitable to crush all kinds of ores and rocks with medium hardness and above.Hydraulic cone crusher adopts grease seal to isolate dust and lubricants,therefore

mill/sbm crusher for stone with mohs.md at master mill

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

2022/sbm rock crushing plant medium hardness stone

Contribute to naicha22/2022 development by creating an account on GitHub.

McLanahan What Type of Crusher Is Best for

2021325 Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides

Jaw Plates: How to Choose the Right One for Different Types of Jaw Crushers

2023215 Model and specifications of jaw crushers-What types of jaw plate material you should choose may depend on different specifications, feed size and impact load. The hardness of the material-The hardness of the material is also an important factor in choosing the jaw plate. The material hardness determines the toughness and strength

sbm/sbm stone crushers for crush hardness rocks.md at

``` sbm stone crushers for crush hardness rocksJaw Crushers for sale eBay Make Offer 220V Adjust Jaw Crusher Rock Slag Steel Coal Stone Coom Crush machine Store USA Purchasing Jaw Crusher Machines on eBay: a Guide Whether you're just getting into the business of mining or are looking for an upgrade China 50 200tph Hot Sale Mining

sbm/sbm iron ore crush hardness.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Jaw Crusher For Sale Can Process All Kinds Of Rocks

APJ-E jaw crusher machine price range: $18000-$210000. Simple structure, relatively easy operation and maintenance. It is suitable for coarse crushing and primary crushing of materials with medium hardness and medium particle size. Low investment cost, suitable for small and medium-sized production lines or limited space.

Choosing the right crusher for rock, stone, concrete and

These crushers generate an enormous amount of power and are able to crush a variety of materials including hard abrasive stone like granite. Impact Crushers. Impact crushers rely on velocity and sudden impact inside the crusher to break the rock and stone. They provide a high reduction rate, but because of how they crush, they’re best suited

Crushing in Mineral Processing Eastman Rock Crusher

2020420 The products can be extracted immediately after the gyratory crusher as 0-32 mm or 0-63 mm fractions, if necessary; these materials are used when stability is needed for the given construction application. The tertiary stage produces fractions in sizes ranging from 0-2 mm to 16-32 mm. These products are used in asphalt and concrete.

A Guide to Types of Jaw Crushers for Crushing Rocks and

2023215 Jaw crushers are commonly used in the mining and aggregate industry for breaking down different types of materials, such as rocks and minerals, into smaller pieces. There are several types of jaw crushers available in the market, each with different capabilities and specifications. In this article, we will discuss the most common types of

- مطحنة توربو المنتج

- الشركات السويدية لصناعة المعدات الثقيلة

- الصين GF الثقيلة كسارة

- مطلوب كسارة في سلطنة عمان

- شركة هلتيير لصناعة المعدات الثقيلة

- اسعار بلاطات الكسارة

- آلات التصوير المتطورة

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- الهيكل الاداري محجر فوسفات

- وكيل ماكنات تطريز كوريه بالجزائر

- أفران صناعة المعادن

- السواقى والبريمات فى المطاحن