أرسل لنا رسالة

design parameters of primary crusher

Primary Crusher an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the

get priceWhat Is Primary, Secondary, and Tertiary Crushing?What is a Primary Crusher? Fabo

Optimizing processing parameters of stone crushers through

202211 For optimization, Taguchi Design of Experiment (DOE) have been perform by considering eccentric speed, feed rate, closed side settingthrow as the process

get price:Mining EngineeringCATIAP3V5R15Mining Equipment

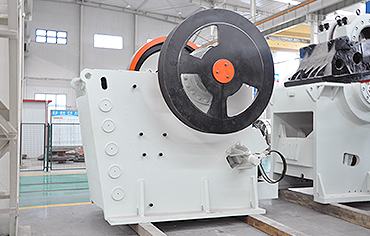

Improvement of Jaw Crusher Design by DEMFEA

2022130 Crushing Pressure created by jaw crusher depends on design parameters such as; drive shaft eccentricity distance, toggle plate position, drive shaft revolution

get price

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022920 Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

get price: Martin Murithi

Mathematical Modeling and Multi-Criteria

2023517 Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a single-roll gyratory shaft crusher, designed for crushing strong rocks, was

get price

Application of analytical hierarchy process to selection of primary crusher

201471 Selection of crusher required a great deal of design based on the mining plan and operation input. Selection of the best primary crusher from all of available

get price:Mohammad Javad Rahimdel, Mohammad AtaeiPublish Year:2014

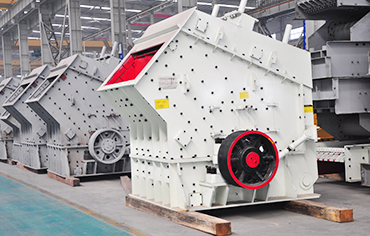

(PDF) Study on the crushing mechanism and parameters of

2022331 Through the rotating speed parameters provided by the enterprise, the linear speed of its current crusher impeller is generally 50–60 m/s, while the linear speed

get price

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and

get price:N S Golikov, I P TimofeevPublish Year:2018

Stone Crushers: A Technical Review on Significant Part of

2022513 Some key structural parameters like bottom angle of mantle, eccentric angle, length of parallel zone have also put major impact on the crushed material quality

get price

Crusher an overview ScienceDirect Topics

Roll Crushers. A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design. Roll crushers are generally not used as primary crushers for hard ores. Even for softer ores, like chalcocite and chalcopyrite they have been used as secondary crushers. Choke feeding is not advisable as it tends to produce particles of

get price

(PDF) Influence of jaw crusher parameters on the

2020319 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the

get price

Finite Element and Multibody Dynamics Analysis

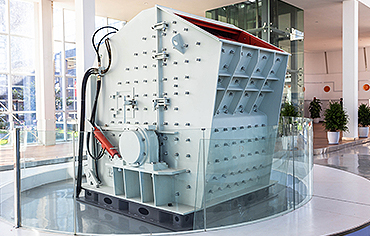

20221229 Fladvad and Onnela [] studied the influence of jaw crusher parameters on the quality of primary crushed aggregates.In the hammer crusher (Figure 2), hammerheads of high wear resistance and

get price

Assessment of the effect of blasthole design parameters on

2020113 The most appropriate design parameters were determined as 15 m hole length, 102 mm hole diameter, 3–3.25 m burden, 3.5–3.75 m distance between holes and 3–3.5 m stemming length. The acceptable cost interval for similar rock units was proposed by deriving the graph of the relationship between blasthole diameter and total unit cost.

get price

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017630 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

get price

Superior™ MKIII 60-89 primary gyratory crusher Metso

The core of the Superior™ MKIII 60-89 primary gyratory crusher is the robust design. Resistant U-shaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy one-piece main shaft makes the Superior™ MKIII 60-89 primary gyratory crusher efficient and lasting, but easy to

get price

DEM-based design of feed chute to improve performance

202171 Section snip The crushing plant of the Sarcheshmeh copper complex. The crushing plant of the Sarcheshmeh consists of a primary crusher (gyratory) with a nominal capacity of 5000 t/h, primary screening unit with six vibrating screens and three 7-ft secondary (standard cone) crushers which with a throughput of 787 t/h and six 4-ft

get price

(a) Structure diagram and (b) functional principle diagram of cone crusher.

For optimization, Taguchi Design of Experiment (DOE) have been perform by considering eccentric speed, feed rate, closed side settingthrow as the process parameters.L09 orthogonal array have

get price

Design of a crushing system that improves the crushing

2016210 has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers . A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone

get price

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022920 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

get price

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

get price

Crushing Plant Design and Layout Considerations 911

2016414 design, so that they can identify ways of reducing overall electrical power consumption. • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001)

get price

(PDF) Failure analysis of jaw crusher and its

201571 The primary crusher is essential equipment employed for comminuting the mineral in processing plants. Any kind of failure of its components will accordingly hinder the performance of the plant.

get price

(PDF) Primary crusher site selection in open pit mines: Case

202111 This study covers an attempt to find the optimal location for primary crusher in order to support the expansion of Sungun copper mine, which is the second largest open pit mine in Iran. Recent

get price

A review of modeling and control strategies for cone crushers

2021815 The author did not address the control of the cone crusher itself but discussed controlling the feed rate to the primary crusher by manipulating the speed of a vibrating feeder in a feedforward capacity. The effect of the variation in the flowsheet layout and design parameters on the quality and capacity of the crushed product was

get price

Primary Crushing 911 Metallurgist

2016226 The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher for this service

get price

Aggregate Production Optimization in a Stone-Crushing

202028 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

get price

(PDF) COMPARISON OF SECONDARY CRUSHING

2020920 Selection of crusher required a great deal of design based on the mining plan and operation input. Selection of the best primary crusher from all of available primary crushers is a Multi-Criterion

get price

SAG Mill Grinding Circuit Design 911 Metallurgist

201666 Aside from parameters fixed at design (mill dimensions, installed power, and circuit type), the major variables affecting AG/SAG mill circuit performance (throughput and grind attained) include: Compounding the challenge of feed size is the fact that for many ores, the overall coarseness of the primary crusher product is correlated to feed

get price

Study on the technical parameters model of the functional

A cone crusher is a machine that crushes rock materials with high efficiency and low power consumption; it is one of the typical road construction equipment. To improve the production efficiency, mechanical performance, and crushing performance of the cone crusher, thus increasing profit, this study used Discrete element method (DEM) particle analysis

get price

Optimizing processing parameters of stone crushers through

202211 For optimization, Taguchi Design of Experiment (DOE) have been perform by considering eccentric speed, feed rate, closed side settingthrow as the process

get price

Improvement of Jaw Crusher Design by DEMFEA

2022130 Crushing Pressure created by jaw crusher depends on design parameters such as; drive shaft eccentricity distance, toggle plate position, drive shaft revolution

get price

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022920 Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

get price

Mathematical Modeling and Multi-Criteria

2023517 Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a single-roll gyratory shaft crusher, designed for crushing strong rocks, was

get price

Application of analytical hierarchy process to selection of primary crusher

201471 Selection of crusher required a great deal of design based on the mining plan and operation input. Selection of the best primary crusher from all of available

get price

(PDF) Study on the crushing mechanism and parameters of

2022331 Through the rotating speed parameters provided by the enterprise, the linear speed of its current crusher impeller is generally 50–60 m/s, while the linear speed

get price

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and

get price

Stone Crushers: A Technical Review on Significant Part of

2022513 Some key structural parameters like bottom angle of mantle, eccentric angle, length of parallel zone have also put major impact on the crushed material quality

get price

Crusher an overview ScienceDirect Topics

Roll Crushers. A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design. Roll crushers are generally not used as primary crushers for hard ores. Even for softer ores, like chalcocite and chalcopyrite they have been used as secondary crushers. Choke feeding is not advisable as it tends to produce particles of

get price

(PDF) Influence of jaw crusher parameters on the

2020319 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the

get price

Finite Element and Multibody Dynamics Analysis

20221229 Fladvad and Onnela [] studied the influence of jaw crusher parameters on the quality of primary crushed aggregates.In the hammer crusher (Figure 2), hammerheads of high wear resistance and

get price

Assessment of the effect of blasthole design parameters on

2020113 The most appropriate design parameters were determined as 15 m hole length, 102 mm hole diameter, 3–3.25 m burden, 3.5–3.75 m distance between holes and 3–3.5 m stemming length. The acceptable cost interval for similar rock units was proposed by deriving the graph of the relationship between blasthole diameter and total unit cost.

get price

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017630 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

get price

Superior™ MKIII 60-89 primary gyratory crusher Metso

The core of the Superior™ MKIII 60-89 primary gyratory crusher is the robust design. Resistant U-shaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy one-piece main shaft makes the Superior™ MKIII 60-89 primary gyratory crusher efficient and lasting, but easy to

get price

DEM-based design of feed chute to improve performance

202171 Section snip The crushing plant of the Sarcheshmeh copper complex. The crushing plant of the Sarcheshmeh consists of a primary crusher (gyratory) with a nominal capacity of 5000 t/h, primary screening unit with six vibrating screens and three 7-ft secondary (standard cone) crushers which with a throughput of 787 t/h and six 4-ft

get price

(a) Structure diagram and (b) functional principle diagram of cone crusher.

For optimization, Taguchi Design of Experiment (DOE) have been perform by considering eccentric speed, feed rate, closed side settingthrow as the process parameters.L09 orthogonal array have

get price

Design of a crushing system that improves the crushing

2016210 has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers . A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone

get price

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022920 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

get price

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

get price

Crushing Plant Design and Layout Considerations 911

2016414 design, so that they can identify ways of reducing overall electrical power consumption. • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001)

get price

(PDF) Failure analysis of jaw crusher and its

201571 The primary crusher is essential equipment employed for comminuting the mineral in processing plants. Any kind of failure of its components will accordingly hinder the performance of the plant.

get price

(PDF) Primary crusher site selection in open pit mines: Case

202111 This study covers an attempt to find the optimal location for primary crusher in order to support the expansion of Sungun copper mine, which is the second largest open pit mine in Iran. Recent

get price

A review of modeling and control strategies for cone crushers

2021815 The author did not address the control of the cone crusher itself but discussed controlling the feed rate to the primary crusher by manipulating the speed of a vibrating feeder in a feedforward capacity. The effect of the variation in the flowsheet layout and design parameters on the quality and capacity of the crushed product was

get price

Primary Crushing 911 Metallurgist

2016226 The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher for this service

get price

Aggregate Production Optimization in a Stone-Crushing

202028 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

get price

(PDF) COMPARISON OF SECONDARY CRUSHING

2020920 Selection of crusher required a great deal of design based on the mining plan and operation input. Selection of the best primary crusher from all of available primary crushers is a Multi-Criterion

get price

SAG Mill Grinding Circuit Design 911 Metallurgist

201666 Aside from parameters fixed at design (mill dimensions, installed power, and circuit type), the major variables affecting AG/SAG mill circuit performance (throughput and grind attained) include: Compounding the challenge of feed size is the fact that for many ores, the overall coarseness of the primary crusher product is correlated to feed

get price

Study on the technical parameters model of the functional

A cone crusher is a machine that crushes rock materials with high efficiency and low power consumption; it is one of the typical road construction equipment. To improve the production efficiency, mechanical performance, and crushing performance of the cone crusher, thus increasing profit, this study used Discrete element method (DEM) particle analysis

get price- مطحنة توربو المنتج

- الشركات السويدية لصناعة المعدات الثقيلة

- الصين GF الثقيلة كسارة

- مطلوب كسارة في سلطنة عمان

- شركة هلتيير لصناعة المعدات الثقيلة

- اسعار بلاطات الكسارة

- آلات التصوير المتطورة

- حفارات هيدروليكية أسعار الإيجارات كسارة الصخور

- الهيكل الاداري محجر فوسفات

- وكيل ماكنات تطريز كوريه بالجزائر

- أفران صناعة المعادن

- السواقى والبريمات فى المطاحن